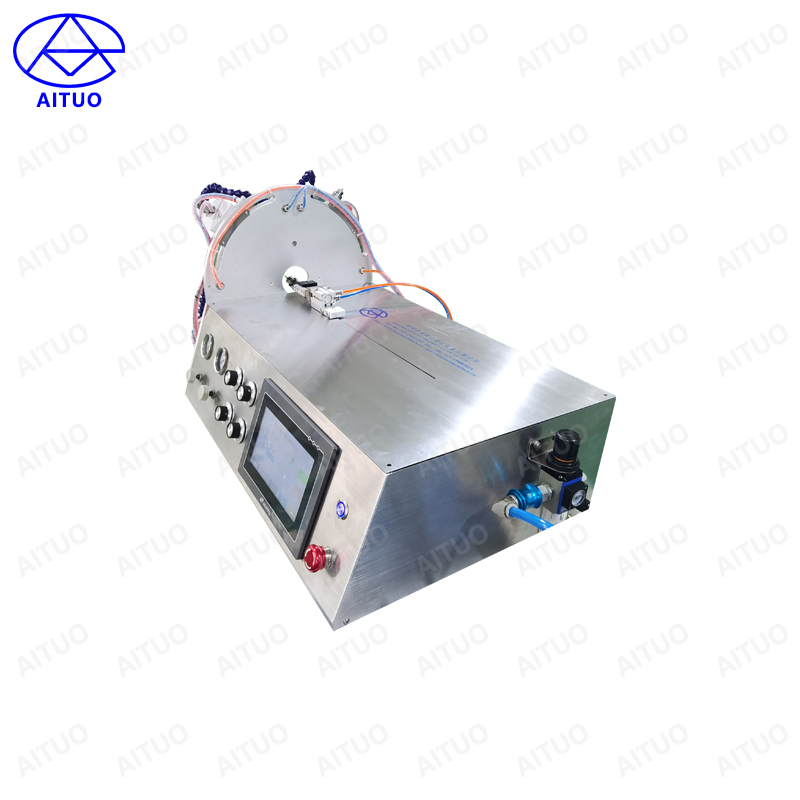

AM20104 Four-axis CNC punching machine for plastic catheters

Model: AM20104

Working voltage: AC 220V/10A/50HZ

Power: 0.4 KW

Air pressure: 0.5-0.8 Mpa

Ambient temperature: -20℃+50℃

Punching speed: 2S/hole Four-axis:2S for 4holes(depend on different material)

Weight: 35KG

Size: 740×420×400 mm

×Enter your message

Product Description

AM20104 Four-axis CNC punching machine for plastic catheters

Main features

This equipment is mainly used for drilling medical plastic catheters. It adopts manual feeding and consists of clamping,handling and a four-way punching component. The equipment has a compact structure. The tool holder adopts a 4-way spindle drilling, which can adapt to processing tools of 0.3-4.5mm. Equipped with reset ejection structure, the waste is ejected from the knife when resetting. The punching stroke, punching quantity, punching angle and spacing can be adjusted freely.

Technical parameters

Clamping stroke: 400mm

Feed speed: CNC adjustment, up to 100mm/s

Hole spacing: CNC adjustment

Adjustment accuracy: ±0.02mm

Motorized spindle speed: 0~6000RPM stepless speed regulation

Motorized spindle runout: ≤±0.03mm

Single spindle adjustment angle: 30 degrees (with scale)

Z-axis module accuracy: ±0.02mm

Hole size range: 0.3-8mm

catheter diameter range: 1.5-6.0mm

Applicable materials: PVC, PU, HDPE, LDPE, PP, PA, PEBAX, FEP, etc

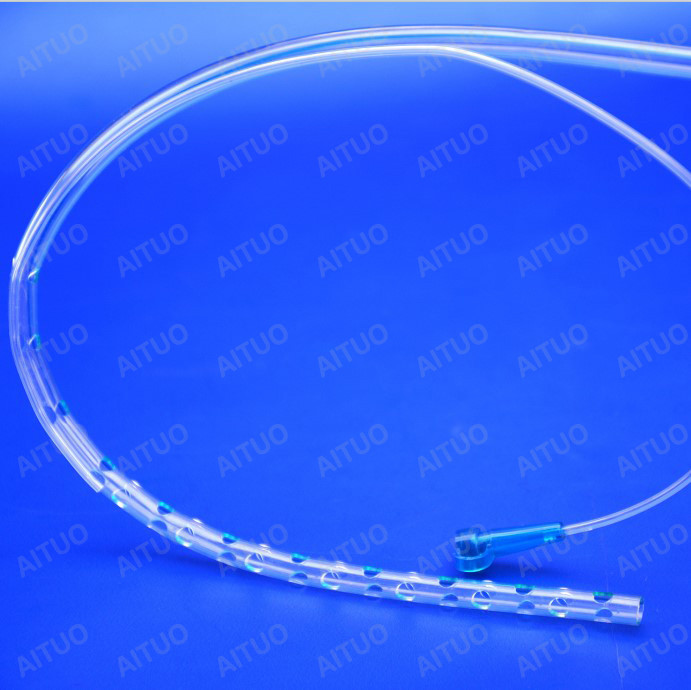

Application products: Medical catheter and other plastic catheters