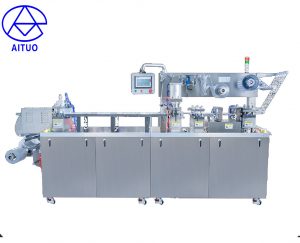

AM60101 medical blister packing machine

Equipment Model: AM60101

Punching times: 15-42times/min

Maximum molding area and depth: Length 140*width 260*depth 26mm (PVC hard 25-60 silk)

Standard stroke range: 40mm—140mm

Compressed air pressure: 0.6-0.8MPa

Dimension: Width 3300×Depth 720×Height 1750mm

Weight: 1400KG

×Enter your message

Product Description

Performance features:

1. easy to adjust: forming, heat sealing, playing batch number, indentation, punching and other devices all adopt the mandrel with rack and pinion for positioning; shaking the crank handle, all kinds of devices can move easily and freely on the mandrel; the machine is equipped with a ruler, which is convenient for correction and rapid and accurate positioning.

2. adjustable stroke: mechanical traction or servo traction is adopted, which increases the adjustable range of traction stroke and can adapt to the packaging of various sizes of pharmaceutical plates.

3. Simple operation: the machine is easy to operate with heating of the plate, positive pressure forming, upper and lower screen pattern, cylinder heat sealing, automatic feeding, automatic creasing and marking of batch number, automatic punching and cutting section.

4. different forming shapes: positive pressure air forming plus configuration of mechanical punch ensures uniform and stiff blister forming, suitable for packaging of larger sizes or special shaped objects such as hair film, clay film of cosmetics and large dense pills of Chinese medicine.

5. According to the choice of material feeding method: with special automatic feeder, such as peristaltic pump for liquid, piston pump for cream and paste, ceramic pump for more accurate filling, automatic sweeper for solid regular shape, etc., in order to adapt to different viscosity and different physical forms of cosmetics, drugs, food and other materials automatically feeding, with a wide range of application (individual irregular materials need manual filling).

6. Convenience of mold replacement: the main drive part adopts parallel shaft helical gear reducer, and the molds for forming, heat sealing and creasing are positioned by shaw nails and fastened by pressure plates, which are accurately positioned and convenient for mold replacement.

7. Flexible one-piece or split design: For the convenience of machine access to the workshop, the machine body can be split according to user requirements.

8. secondary forming device: individual bubble shape depth is large, in order to ensure the uniformity of thickness of bubble cover forming, secondary forming device can be added to the forming device.

9. More options: optional cursor tracking device; optional servo traction or mechanical traction device; optional increase of machine glass cover; optional ink-jet coding (word) device; optional increase of easy-break line device; optional increase of dashed line cutting device; optional output belt device, etc.

Equipment Parameter:

Equipment Model: AM 60101

Punching times: 15-42times/min

Maximum molding area and depth: Length 140*width 260*depth 26mm (PVC hard 25-60 silk)

Standard stroke range: 40mm—140mm

Total power supply: 380V/50Hz 8.2Kw

Compressed air pressure: 0.6-0.8MPa

Compressed air consumption: ≥0.3m3/min

Cooling method: Cooling cycle or water cooling

Noise index: < 65dB

Size:3300×720×1750mm

Weight: 1400kg

Production process: Blister forming, feeding, heat laminating, punching, and finished product conveying are completed at one time

Applied Range:

- Cosmetics: such as water bang bang cream, clay film, hair mask, two-color egg mask, lyophilized mask, shampoo, shower gel, lipstick, perfume, serum, gel, lyophilized powder, etc.

- Pharmaceutical products: pills, tablets, capsules, powders, etc.

- Food items: mouthwash, chili sauce, tea, honey, ginger water, ketchup, etc.

- Other items: e-cigarettes, electronic cigarettes, dental needles, tweezers, tattoo needles, etc.